Blanching is a crucial step in food processing, used to preserve color, texture, and nutrients while ensuring food safety. However, different food products require customized blanching settings to achieve optimal results. From vegetables and fruits to meat and seafood, selecting the right blanching machine with tailored features is essential for efficient processing.

This article explores how blanching machines can be customized for different food types and their key applications in the food industry.

🔹 1. Blanching Machines for Vegetables

✅ Application:

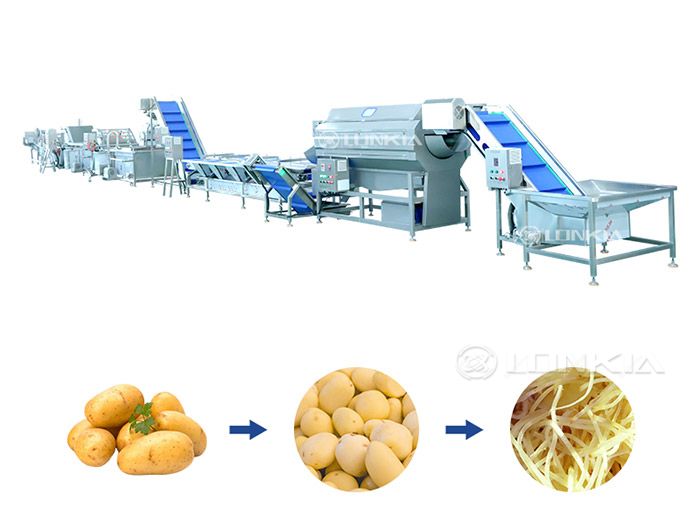

Vegetables like carrots, broccoli, spinach, potatoes, and beans require blanching to deactivate enzymes, enhance color, and prepare for freezing or drying.

🔧 Customization Features:

- Adjustable Temperature & Time – Prevents over-softening and nutrient loss.

- Hot Water or Steam Blanching Options – Ideal for different vegetable textures.

- Continuous Conveyor Systems – Ensures high-speed processing for large batches.

🏭 Industries Using It:

✔️ Frozen vegetable processing

✔️ Dehydrated vegetable production

✔️ Canned vegetable manufacturers

🔹 2. Blanching Machines for Fruits

✅ Application:

Fruits such as apples, peaches, and berries are blanched to soften peels, maintain texture, and improve juicing or canning efficiency.

🔧 Customization Features:

- Short-Time High-Temperature (STHT) Processing – Prevents excessive softening.

- Precision Cooling Systems – Maintains fruit firmness after blanching.

- Peel Removal Assistance – Helps in industrial fruit processing.

🏭 Industries Using It:

✔️ Juice & puree production

✔️ Canned fruit processing

✔️ Dried fruit manufacturing

🔹 3. Blanching Machines for Meat & Seafood

✅ Application:

Meat and seafood blanching is used for reducing bacteria, improving texture, and preparing for further processing.

🔧 Customization Features:

- High-Temperature Blanching (Above 82°C/180°F) – Ensures microbial safety.

- Controlled Water Circulation – Reduces shrinkage and texture loss.

- Automated Filtration System – Keeps water clean to maintain hygiene.

🏭 Industries Using It:

✔️ Processed meat production (sausages, deli meats)

✔️ Seafood pre-cooking for freezing

✔️ Poultry and fish processing

🔹 4. Blanching Machines for Nuts & Seeds

✅ Application:

Blanching helps remove skin, reduce bitterness, and enhance flavor in almonds, peanuts, and sunflower seeds.

🔧 Customization Features:

- Water Jet Skin Removal – Efficiently peels nuts without damage.

- Precise Temperature Control – Prevents over-processing.

- Drying Integration – Ensures nuts are ready for roasting or further processing.

🏭 Industries Using It:

✔️ Nut and seed processing

✔️ Nut butter production

✔️ Snack food manufacturing

🔹 Choosing the Right Blanching Machine for Your Industry

🔥 Key Customization Factors to Consider:

✔ Heating Method: Steam vs. water blanching based on food type.

✔ Processing Capacity: Batch vs. continuous conveyor systems.

✔ Automation Level: Fully automated vs. semi-automated models.

✔ Material Handling: Delicate vs. robust food textures.

🚀 Why Invest in a Customized Blanching Machine?

✔ Improves processing efficiency

✔ Enhances food quality & consistency

✔ Reduces waste & production costs

✔ Ensures compliance with food safety standards

At LONKIA Machinery, we provide customized blanching machines tailored to specific food processing needs. Contact us today to find the perfect solution for your business!