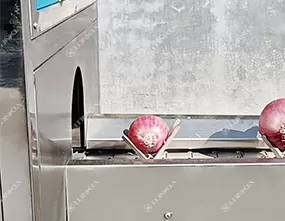

The Onion Top and Tail Cutter Machine is specially designed for precision cutting of onion ends, providing a seamless start to the onion processing workflow. This machine requires manual feeding, with an ergonomic design that makes the feeding process efficient and comfortable. It supports continuous operation, ensuring high productivity and smooth integration with additional downstream equipment for comprehensive onion processing solutions.

Onion Top and Tail Cutter Machine

Key Features

- Ergonomic Manual FeedingThe onion top and tail cutter machine’s optimal feeding height minimizes operator fatigue, enhancing comfort and efficiency during manual loading.

- High Cutting PrecisionOnion root cutting machine accurately removes both the tip and tail of onions, maintaining the onion's core structure and minimizing waste. Consistent cutting quality for onions of varying sizes and shapes.

- Continuous OperationThe onion cutting machine is capable of non-stop processing, making it ideal for large-scale production lines. Ensures steady output to meet industrial processing demands.

- Integration-Ready DesignEasily integrated into automated production lines, the onion top and tail cutter machine works in conjunction with onion peeling machines, washing and cutting machines, conveyors and sorting lines to simplify the peeling process and realize a complete processing solution that efficiently supports fully automated onion processing lines.

Application

- Fresh Onion Packaging: Prepares onions for consumer-ready packaging.

- Onion Peeling Lines: Serves as a pre-processing step for peeling machines.

- Processed Onion Products: Ideal for lines producing diced, sliced, or frozen onions.

- Industrial Kitchen and Catering: Speeds up preparation for bulk onion processing.

Prev Article: Garlic Clove Separator With High Efficiency

Next Article: Vegetable Dicing Machine With High Capability