Our Frozen French Fries Processing Line is engineered to produce premium-grade frozen fries, optimizing every step of the process for maximum efficiency, quality, and consistency. Designed for large-scale production, this line integrates advanced technologies to preserve the flavor, texture, and nutritional value of potatoes while ensuring high throughput and minimal waste.

Frozen French Fries Processing Line

Detail Picture

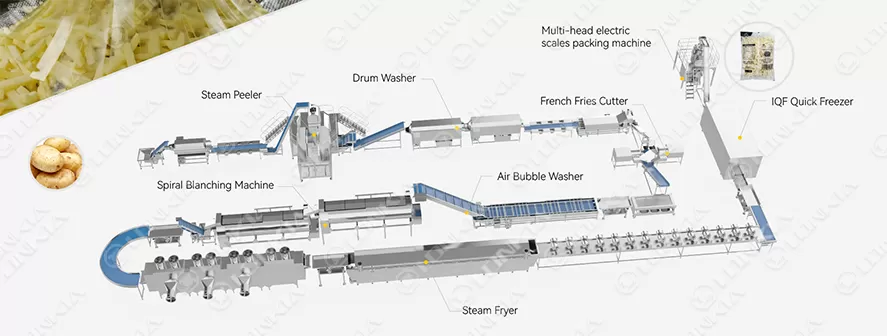

Processing Workflow

- Step 1: Steam PeelingThe first step in the frozen French Fries processing line is steam peeling. By softening the potato skin with high-pressure steam, the steam peeling machine efficiently removes the skin without damaging the flesh, ensuring excellent product appearance and texture while minimizing peeling losses.

- Step 2: Brush Roller WashingBrush roller washing machine gently cleans the potatoes, removing dirt, residual pesticides, and any remaining skin particles. The robust brushes ensure thorough cleaning while minimizing damage to the potatoes, preserving their shape and quality.

- Step 3: Hydraulic CuttingHydraulic cutting machine knives are used for precise, uniform cuts, ensuring consistent French fries shape and size. This step enhances the processing efficiency, reducing waste and improving the final product's visual appeal.

- Step 4: Spiral BlanchingThe spiral blanching machine ensures uniform heat treatment, preserving the natural color and texture of the potatoes. The blanching process is optimized for both flavor and texture, preventing discoloration and enhancing the fries' crispiness after frying.

- Step 5: Air DryingThe air drying system of vegetable dewatering machine removes excess moisture after blanching, ensuring the fries maintain the ideal moisture content for optimal frying results. This step in the the frozen French Fries processing line improves frying efficiency, reduces oil absorption, and enhances the final texture of the fries.

- Step 6: Steam FryingThe Steam Frying Machinein the frozen French Fries processing line uses steam as a heat source. Through the circulation of steam in the duct, the frying oil is quickly heated, and the French fries are fried to golden and crispy in a short time. This equipment not only improves the quality of French fries, but also makes the entire production process more efficient and energy-saving.

- Step 7: Oil DrainingThe oil draining system removes excess oil after frying, ensuring a healthier end product with minimal oil content. Helps maintain the desired texture while reducing fat intake, contributing to a healthier consumer experience.

- Step 8: FreezingFluidized bed freezing locks in the fries’ freshness, texture, and nutritional value, ensuring a longer shelf life without compromising quality. This process ensures uniform freezing, preventing the fries from sticking together and ensuring they retain their crispness when cooked. It is an essential step in the fully automatic frozen French Fries production line.

Application

-

French Fries

French Fries

-

Potato Chips

Potato Chips

-

Potato Wedges

Potato Wedges

-

Wave French Fries

Wave French Fries

-

Banana Slice

Banana Slice

Core Features and Benefits

- High-Quality Output: Our frozen French Fries processing line ensures that each batch of French fries meets the highest standards for taste, texture, and appearance, creating a premium product for your customers.

- Efficiency and Automation: Fully automated systems improve production speed while minimizing labor costs and reducing human error. Capable of handling up to 5 tons per hour, this fully automatic frozen French Fries production line is perfect for large-scale production needs.

- Consistent Product Quality: With integrated quality control systems, the line ensures uniform size, texture, and color across all fries, giving your product a market-ready, high-quality finish.

- Customizable for Different Potato Varieties: Our French Fries plant is adaptable to various potato varieties, ensuring versatility in meeting specific market preferences. It allows adjustments for different frying profiles, including options for crinkle-cut, straight-cut, and other specialty cuts.

Prev Article: Reliable Frozen Vegetable Processing Line

Next Article: Best Fresh Corn Processing Line