The Tomato Dicing Processing Line is designed to streamline the production of diced tomatoes, from cleaning and peeling to dicing, packaging, and sterilization. This advanced line ensures precision, hygiene, and efficiency, catering to the growing demand for high-quality diced tomato products in both industrial and retail markets. The system is fully customizable to adapt to specific production capacities and packaging requirements.

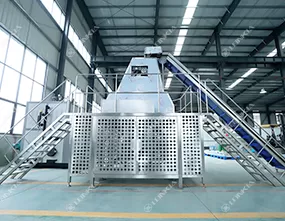

Tomato Dicing Processing Line

Detail Picture

Processing Workflow

- Step 1: Tomato WashingThe first step in the tomato dicing processing line is cleaning. Specialized bubble washing machine, gently clean tomatoes, removing dirt, pesticides, and debris without damaging the fruit.

- Step 2: PeelingThe cleaned tomatoes enter the peeling section of the diced tomatoes processing line, which usually utilizes highly efficient steam peeling technology. Steam peeling machine uses high temperature steam to effectively loosen the tomato skin. This method causes less damage to the pulp and maximizes the original nutrition and taste of the tomato.

- Step 3: DicingHigh-precision tomato dicing machines deliver uniform cuts with minimal loss, enhancing product consistency and quality. The adjustable settings allow flexibility in dicing sizes to meet various market demands.

- Step 4: PackagingAutomated packaging systems ensure the diced tomatoes are hygienically packed into pouches, cans, or containers, ready for retail or bulk supply.

- Step 5: SterilizationThe final step in the tomato dicing processing line is sterilization. Packaged products undergo rigorous and thorough sterilization to effectively extend shelf life while retaining maximum flavor and nutrients.

Application

-

Tomato Paste

Tomato Paste

-

Tomato Beverage

Tomato Beverage

-

tomato beverage

tomato beverage

-

Tomato Paste

Tomato Paste

-

Tomato Paste

Tomato Paste

Core Features and Benefits

- High Efficiency and Capacity: The tomato dicing processing line can process up to several tons per hour, making it ideal for large-scale tomato production. Automated operations reduce manual intervention, ensuring consistent output and saving labor costs.

- Advanced Peeling Technology: Steam peeling ensures clean and efficient skin removal with minimal waste. Retains the natural texture, color, and taste of tomatoes.

- Customizable Dicing Options: By adjusting the knife size, the dicing machine can cut tomatoes into various sizes to meet customer needs, serving diverse food processing applications like pizza sauce and salads. Its high-speed operation enhances cutting efficiency and accuracy, offering efficient and customizable solutions.

- Extended Product Shelf Life: Efficient sterilization techniques in the diced tomatoes processing line ensure product safety and freshness. Packaging solutions protect diced tomatoes from oxidation and spoilage.

Prev Article: Industrial Cucumber Canning Processing Line

Next Article: High Efficient Salad Processing Line For Sale